M-LOK vs Picatinny: Which Rail System Wins?

Published on: October 2, 2025

Reading time: 12 mins 32 sec

Choosing a rail system changes how your rifle feels and how you mount gear. It also affects weight and upgrade options down the line.

Both M-LOK and Picatinny work well, but they serve different needs. Pick the wrong one and you may deal with extra bulk, adapters, or limited accessory choices.

M-LOK uses open slots that cut material for a lighter, slimmer profile. This makes rifles easier to handle and reduces front-end weight.

Picatinny uses raised rails and has long been the standard for toughness and wide compatibility. It’s strong and reliable, but it usually adds more bulk.

This guide breaks down the real differences so you can match the right system to your style of shooting.

Highlights

- Choose M-LOK for competition shooting where weight savings and quick transitions matter most.

- Pick Picatinny if you own significant rail-mounted accessories or need maximum compatibility.

- Opt for hybrid handguards when you want lightweight ergonomics without sacrificing optic mounting.

- Select M-LOK for new builds to save 40-50% in weight and reduce bulk.

- Go with Picatinny for heavy-duty tactical use or when working with legacy equipment.

Understanding Rail System Evolution: From Weaver to Modern Standards

The Military Origins of Picatinny Rails

The Picatinny rail grew out of earlier rail ideas and work by designers like Dick Swan in the 1980s. Picatinny Arsenal later measured and standardized rail dimensions so parts would work together.

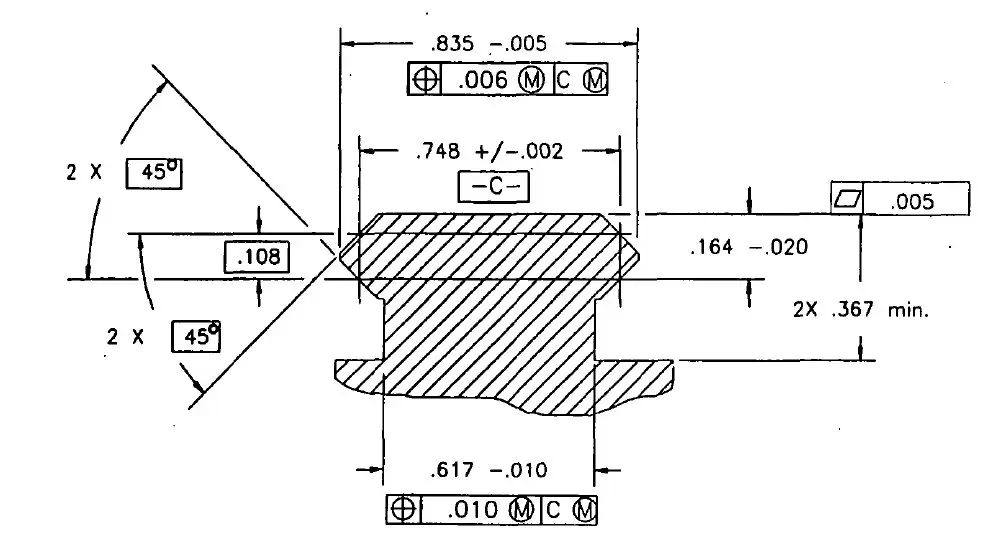

In the early 1990s, engineers at Picatinny consolidated measurements from many Weaver-style rails and created a formal specification. The result became MIL-STD-1913 on February 3, 1995.

MIL-STD-1913 sets exact slot dimensions: a locking slot width of 0.206 inches, center spacing of 0.394 inches, and a slot depth of 0.118 inches. Those numbers let most MIL-STD-1913 accessories fit rails made by different makers.

People often confuse Weaver and Picatinny rails. Weaver slots are narrower at about 0.180 inches, so many Weaver accessories fit a Picatinny rail, but some Picatinny accessories won’t fit a Weaver rail.

Full-length quad rails grew very popular in the late 1990s and early 2000s because they let you attach gear on all four sides. They added modularity, but later, lighter slot-based systems became popular for handling and weight savings.

Magpul’s Innovation: The Birth of M-LOK

Magpul first showed the Masada rifle in 2007 with vented polymer handguards. These slots hinted at a new negative-space system for mounting gear.

Two years later, the MOE handguards brought that idea to AR-15 rifles. They gave shooters a lightweight slot option, but it came with one big drawback.

The MOE design needed rear access to mount parts, which limited its use on free-float handguards. It also relied on weld nuts that had to be set inside the rail.

Magpul worked on a fix for years. In 2014, they released M-LOK as a stronger and more flexible evolution of MOE.

The new system used metric slots and rotating T-nuts. This allowed blind mounting, making it perfect for modern free-float rails.

By that time, KeyMod had already been on the market since 2012. Both promised lighter setups and more flexibility than bulky quad rails.

Magpul also made a key business move. They offered M-LOK licensing for free but required makers to get approval first.

This wasn’t fully open-source like KeyMod. But the controlled license kept all M-LOK products within spec and fully compatible.

That strategy paid off. Today, M-LOK has overtaken KeyMod and become the industry standard for rifles used by both civilians and the U.S. military.

Technical Specifications

Picatinny Rail System Mechanics

The Picatinny rail is a raised, T-shaped rail with square slots cut between the ridges. That shape is what gives the rail its distinctive look and lets mounts lock into place.

Accessories clamp to the rail and engage the slots with recoil lugs or bolts. When mounted correctly, the hardware bites into the rail and resists movement under recoil.

Because of that locking geometry, Picatinny setups are widely used for heavy optics and mission-critical gear. You still need a good mount and the right torque to keep things steady.

Full-length quad rails keep raised rails on all four sides, so they use more aluminum than slot-only handguards. That extra material adds weight but gives mounting space everywhere.

You’ll often see numbers stamped along many Picatinny rails. Those numbers make it easier to return an accessory to the exact same spot, which helps when you need a repeatable zero.

Building a true MIL-STD-1913 rail requires tight machining tolerances and careful quality control. If the dimensions wander, mounts can bind or won’t seat correctly, so manufacturers use precise CNC work to keep parts within spec.

On many modern handguards, you’ll find M-LOK slots on the sides and a short or full Picatinny strip on top for optics. That hybrid setup gives you lightweight ergonomics where you grip and a familiar Picatinny surface where you mount sights—and with good mounts and installation, it holds your zero as well as any other proper optic interface.

M-LOK System Architecture

M-LOK uses a negative-space design with slots cut into the handguard. This makes it slimmer and lighter than raised rail systems.

Each slot measures about 7mm wide and 32mm long with an 8mm gap between them. These exact dimensions keep parts compatible across licensed brands.

Mounting is simple. You slide the T-nuts into a slot from the front and tighten them without needing rear access like the older MOE system.

The T-nuts rotate 90 degrees when tightened, locking the accessory against the handguard. This cam action gives a firm and reliable hold.

Torque matters when you install parts. Aluminum rails usually need about 35 inch-pounds, while polymer rails take closer to 15 to prevent damage.

M-LOK accessories also use recoil lugs that bite into the slot edges. These lugs stop gear from sliding forward under recoil.

Because the lugs are bi-directional, you can mount accessories from either direction. That flexibility is something KeyMod never offered.

Magpul controls the licensing process but does not charge for it. This keeps the system open while ensuring every M-LOK product follows the same spec and works together.

Direct Dimensional Comparison

The weight gap between quad rails and M-LOK is easy to measure. For example, the BCM QRF-10 quad rail weighs 12.1 ounces in a 10-inch size.

The BCM MCMR M-LOK handguard in the same length comes in at only 6.6 ounces. That’s about 45% lighter without giving up modern mounting options.

Quad rails also take up more space in your grip. The raised rails add bulk and require clearance for attached gear.

M-LOK cuts slots directly into the handguard instead of building rails on all sides. This makes the profile much slimmer and more comfortable to hold.

The extra material in quad rails means more aluminum and machining time. That complexity adds weight and drives up manufacturing costs.

M-LOK handguards are simpler to make with less raw material. While prices vary by brand, the design often makes them more affordable to produce.

Weight and Ergonomics

Quantifying the Weight Difference

M-LOK handguards usually weigh 40–50% less than quad rails of the same length. That difference changes how your rifle feels and handles.

In competition, lighter front ends allow faster target transitions. You move between positions more quickly with less effort.

Hunters also benefit from weight savings. Carrying a rifle all day through rough terrain is easier when every ounce is trimmed.

For duty use, lighter rifles reduce arm strain during long hours on shift. Over time, the smaller weight adds up to noticeably less fatigue.

Quad rails shift the balance point forward. This can make your rifle feel nose-heavy and harder to control in rapid fire.

Grip Comfort and Handling Characteristics

The raised ridges of Picatinny rails create an uncomfortable surface. Without rail covers, the sharp edges dig into your support hand during extended shooting.

M-LOK’s smooth profile feels natural in your hand. The negative-space design eliminates sharp edges and provides a comfortable gripping surface.

Modern shooting techniques favor the C-clamp grip and thumb-over-bore control methods. M-LOK’s slimmer profile accommodates these grips better than bulky quad rails.

Rail covers can solve Picatinny’s comfort problem, but they add weight back into the system. You’re partially defeating the purpose of having a modular rail if you need to cover most of it.

Heat management differs between systems, too. M-LOK’s open design allows better air circulation around the barrel during sustained fire. Picatinny quad rails trap more heat against the barrel. The continuous aluminum rails conduct and hold heat longer than M-LOK’s interrupted surface.

The snag factor becomes relevant when moving through tight spaces. Quad rails catch on gear, clothing, and vehicle interiors more readily than smooth M-LOK handguards.

Profile and Concealability Considerations

If you need to store a rifle in a vehicle or a tight case, slimmer handguards make that easier. M-LOK’s low-profile trims reduce diameter, allowing rifles to fit into smaller spaces.

Teams that move in close quarters often prefer low-profile rails for the same reason. A smooth M-LOK surface is less likely to snag on doorframes, gear, or clothing.

Your hand size matters when you pick a profile. Shooters with larger hands sometimes like the extra diameter that quad rails provide for a fuller grip.

For AR pistols and short-barreled rifles, every bit of saved diameter helps. M-LOK’s slim profile keeps compact builds easier to handle in tight spaces.

Accessory Compatibility and Ecosystem Analysis

Picatinny’s Universal Advantage

Picatinny rails have been around for decades, and almost every accessory maker builds parts to fit them. That wide support makes it easy to find lights, grips, mounts, and more.

You’ll see Picatinny used on rifles, pistols, shotguns, semiautomatics (like the Heckler and Koch Picatinny Rail), and even some machine guns. The standardized rail shows up across many weapon types.

For optics, Picatinny remains a very common mounting choice because it’s proven and familiar to most shooters. Keep in mind, though, that other mounting standards and proprietary mounts are also used.

If you already own Picatinny gear, you can usually move those parts between compliant guns. That cross-use saves money—just make sure the parts are made to spec.

Mounting an accessory on a Picatinny rail is simple: slide it on from the front or rear, set the position, and tighten. The raised sections help seat the part, which reduces fiddly alignment—when the rail and mount meet spec.

Because military and law-enforcement systems still use Picatinny in many roles, manufacturers keep producing pro-grade accessories. That steady demand means plenty of high-quality options for serious applications.

M-LOK’s Modern Ecosystem

Since its release in 2014, M-LOK has grown into the standard for modern rifles. Most big manufacturers now offer M-LOK versions of their most popular accessories.

You’ll find almost every accessory type in M-LOK form. Rail covers, handstops, bipods, sling mounts, and cable guides are all widely available.

New products usually launch with M-LOK compatibility from day one. That steady support keeps the ecosystem expanding year after year. There are many M-LOK accessories one can buy now.

If you need to mount older Picatinny gear, adapters make it simple. Small rail sections attach to M-LOK slots and give you a traditional mounting surface.

Some accessories even work better on M-LOK. Cable management panels, for example, use the slot system for cleaner routing than continuous rails.

Because you only add rails where you want them, the rest of the handguard stays smooth and light. That modular flexibility makes M-LOK easy to tailor to your shooting style.

Adapter Solutions and Hybrid Approaches

M-LOK to Picatinny rail sections come in different lengths. Short 3-slot pieces handle lights or lasers, while longer ones fit bipods or foregrips.

Each adapter adds back some weight. A 5-slot aluminum section usually weighs under an ounce, but it still reduces M-LOK’s weight advantage.

Install adapters with the same care you’d give direct M-LOK mounts. Proper torque keeps them from shifting under recoil and changing your zero.

Hybrid handguards solve the problem another way. They keep M-LOK slots on the sides and bottom, while a full-length Picatinny runs across the top.

This layout has become the standard for modern rifles. You get the slim feel of M-LOK where you want it, and the reliability of Picatinny up top for optics.

It’s also a smooth path for upgrading. You can keep using your older Picatinny gear while moving to M-LOK accessories over time.

Installation and Adjustment

Picatinny Installation Process

- Unload and point your gun safely. First, make sure the firearm is unloaded and keep it pointed in a safe direction before doing anything else.

- Gather tools and inspect parts. Make sure the rail and accessory are clean and you have the right screwdriver, Allen key, or quick-detach tool (and a torque wrench if you have one).

- Loosen the mounting hardware. Back off the thumbscrew, lever, or bolt just enough to open the clamp.

- Fit the mount to the rail. If it slides on, feed it from the rail end; if it’s a clamp-on style, set it over the slots.

- Position where you want it. Note the slot number so you can return to the same spot later.

- Tighten the fasteners to seat the mount. Use the manufacturer’s torque spec if available. It may vary per manufacturer.

- Check alignment and engagement. Verify the mount sits flat, recoil lugs (if present) engage the slots, and any moving parts operate freely.

- Verify function and zero (for optics). Re-check zero after the first range session and re-torque if needed; consider a drop of thread locker on critical fasteners if recommended by the maker.

- Repositioning is the reverse. Loosen, move to a new slot, re-tighten to spec, and confirm alignment and zero again.

M-LOK Installation Process

M-LOK installation requires more careful attention than Picatinny. The T-nut alignment process trips up many first-time users, as even official testing has noted.

- Unload and point your gun safely. First, make sure the firearm is unloaded and keep it pointed in a safe direction before doing anything else.

- Prepare the accessory. Loosen the screws so the T-nuts can rotate freely.

- Insert the T-nuts. Place them into the mounting holes with the threaded stems facing upward.

- Choose your slots. Select the M-LOK slots you want to use, making sure they match the accessory’s mounting length.

- Align and position. Line up the T-nuts with the slots and slide them in from the front or rear of the handguard.

- Engage the lock. Begin tightening; the first quarter turn rotates the T-nuts 90° into the locked position.

- Apply proper torque. Tighten to about 30 in-lbs for aluminum or 15 in-lbs for polymer, using a torque wrench if possible.

- Verify security. Pull gently on the accessory to confirm it’s locked in place; re-tighten if needed.

- Consider professional help. For optics, bipods, or if unsure about torque, a gunsmith can ensure correct installation.

Maintenance and Long-Term Considerations

Carbon buildup affects the two systems differently: Picatinny rails collect residue on raised edges, while M-LOK slots can trap debris inside.

Regular cleaning with brushes, solvents, or compressed air keeps both systems reliable.

Periodic hardware checks are important. Picatinny screws should be inspected for tightness, and M-LOK T-nuts should be confirmed fully rotated and engaged.

Both systems have proven durable under heavy use, with thousands of rounds fired without failures.

Thread wear may also occur after repeated mounting and removal, but quality accessories use hardened steel hardware that resists stripping and maintains longevity.

Common Mistakes and How to Avoid Them

Picatinny Installation Errors

- Over-tightening screws. Exceeding torque limits strips threads or damages mounting hardware. Use the manufacturer’s torque specs (usually 20–30 in-lbs).

- Improper seating. Make sure recoil lugs or rail grabbers fully engage the slot before tightening. Partial seating leads to loose mounts.

- Losing your zero. Always note the slot number when mounting optics. Reinstalling in a different slot can shift your point of impact.

- Skipping thread locker. Apply a small drop of medium-strength (blue) thread locker on critical accessories to prevent screws from backing out under recoil.

M-LOK Installation Problems

- Incorrect T-nut orientation. The T-nut must align with the slot before tightening; failure to rotate it 90° leaves the mount unsecured.

- Under-torquing screws. Loose mounts occur if screws aren’t tightened to spec. Use a torque wrench for critical accessories like optics or bipods.

- Over-torquing hardware. Excess force strips threads or cracks polymer components. Follow manufacturer torque specs (about 30 in-lbs for aluminum, 15 in-lbs for polymer).

- Using the wrong screws. Accessories may require specific screw lengths. Always confirm you’re using the hardware supplied or recommended by the manufacturer.

System Selection Mistakes

- Following trends blindly. Choosing a system because it’s popular online often leads to wasted money. Focus on your real shooting needs.

- Ignoring current gear. If you already own Picatinny accessories, switching entirely to M-LOK may require costly replacements or adapters.

- Forgetting long-term upgrades. Pick a system with wide manufacturer support so you don’t get stuck with limited options later.

- Overlooking your application. Competition, hunting, and tactical use cases all demand different setups. Match your rail choice to your actual mission.

Cost Analysis

Initial Build Costs

Entry-level M-LOK handguards start around $80 – $120 for basic aluminum models. Quality options from established manufacturers run $150 – $250.

Picatinny quad rails typically cost $150 – $250 for basic aluminum construction. The M-LOK price advantage is clear at every quality tier.

Rail covers for Picatinny add $30 – $60 to make the surface comfortable. This narrows the price gap between systems.

M-LOK to Picatinny adapter sections cost $15 – $40, depending on length. Factor these in if you have existing Picatinny accessories.

Complete build cost scenarios show M-LOK saving $50-150 on the handguard alone. That’s money available for better optics or ammunition.

Long-Term Investment Considerations

Accessory compatibility affects long-term value. M-LOK’s growing ecosystem ensures you’ll find compatible products for years.

The resale value of M-LOK rifles currently exceeds comparable Picatinny builds. Market demand favors modern mounting systems.

Switching systems mid-way costs hundreds of dollars. You’ll replace both the handguard and potentially multiple accessories.

Rail choice affects upgrade paths significantly. M-LOK’s modular nature allows incremental upgrades—add accessories only when needed.

Value Proposition Analysis

M-LOK provides the best value for new builds. Lower initial cost plus weight savings justify the investment for most shooters.

Picatinny makes sense if you own significant Picatinny accessories. The higher handguard cost is offset by avoiding accessory replacement.

Budget-conscious builders should prioritize M-LOK. The savings can fund better essential gun components elsewhere.

Premium shooters often choose hybrid systems. M-LOK sides with Picatinny top delivers maximum capability regardless of price.

Conclusion

M-LOK and Picatinny each excel in different areas. M-LOK delivers lighter weight and sleeker ergonomics that improve handling during dynamic shooting. Picatinny offers proven durability and universal compatibility across decades of accessories.

Your choice should match your shooting discipline, existing accessories, and long-term plans.

For modern builds prioritizing weight and handling, M-LOK makes sense as your primary system with Picatinny adapters when needed. For maximum compatibility or heavy-duty applications, Picatinny remains the gold standard.

If you already have a Picatinny or M-LOK rail system and are looking for accessories, Gold Trigger would be more than happy to help you. You may browse our products or call us at 713-485-5773.

Disclaimer: The information provided in this comprehensive rail system comparison guide is for educational and informational purposes only. Firearm modifications and accessory installations can affect weapon safety, performance, and legal compliance. Users are solely responsible for ensuring all modifications and purchases comply with applicable federal, state, and local laws before installation or use.

Improper installation of rail systems or accessories can result in serious injury, equipment damage, or dangerous malfunction. We strongly recommend professional installation by qualified gunsmiths for all firearm modifications and accessories, particularly when changing handguards or mounting critical accessories like optics. This guide does not substitute for manufacturer instructions, proper training, or professional expertise.

Legal requirements vary significantly by jurisdiction. Some states and localities restrict certain firearm modifications, accessories, or configurations. Always verify compliance with your local laws before purchasing or installing any rail system or accessories. When in doubt, consult with legal professionals specializing in firearms law.

Product specifications, availability, pricing, and legal requirements are subject to change without notice. Always verify current information with manufacturers, authorized dealers, and relevant legal authorities before making purchasing decisions. This information reflects current market conditions and may not apply to future product availability or regulatory changes.

Gold Trigger is not responsible for any modifications, installations, or purchases made based on this information. Users assume all risks associated with firearm modification and accessory use, including but not limited to personal injury, equipment damage, legal liability, and performance variations. Always prioritize safety, legal compliance, and proper training over performance modifications or aesthetic preferences.

Comments